Difference between revisions of "Contrib:KeesWouters/shell/static"

Keeswouters (Talk | contribs) m (→'''Reactions forces''') |

Keeswouters (Talk | contribs) m (→'''Reactions forces''') |

||

| Line 379: | Line 379: | ||

* NodalForces * resu * FORC_NODA * 1 * 0.00000E+00 * -1.35387E-08 * 2.63751E-08 * 4.90339E+06 * - * - * - * - * - * - | * NodalForces * resu * FORC_NODA * 1 * 0.00000E+00 * -1.35387E-08 * 2.63751E-08 * 4.90339E+06 * - * - * - * - * - * - | ||

* moments * resu * REAC_NODA * 1 * 0.00000E+00 * - * - * - * -1.35387E-08 * 2.63751E-08 * 5.04036E+06 * 3.06316E+07 * -3.53025E+07 * 2.91360E-07 | * moments * resu * REAC_NODA * 1 * 0.00000E+00 * - * - * - * -1.35387E-08 * 2.63751E-08 * 5.04036E+06 * 3.06316E+07 * -3.53025E+07 * 2.91360E-07 | ||

| − | '' * moments * resu * REAC_NODA * 1 * 0.00000E+00 * - * - * - * -1.35387E-08 * 2.63751E-08 * 5.04036E+06 * 1.91375E+01 * 1.05470E+01 * 2.43516E-08'' | + | ''* moments * resu * REAC_NODA * 1 * 0.00000E+00 * - * - * - * -1.35387E-08 * 2.63751E-08 * 5.04036E+06 * 1.91375E+01 * 1.05470E+01 * 2.43516E-08'' |

Note:<br/> | Note:<br/> | ||

Revision as of 15:03, 12 March 2010

Contents

Static analysis of a shell construction

[ .... under construction .... ]

This contribution is in close cooperation with Bridge.

In this example the following items are discussed:

- preproccesing:

- definition of geometry in Salome

- partitioning of the geometry and groups

- meshing of the geometry

- definition of the groups

- (maybe: python script which makes editing much easier ...)

- static analysis with pressure or force applied on a group or nodes

- postprocessing:

- viewing displacement in Salome

- determination of stresses

- interface ASTK

Definition of the geometry

planar shell

Geometry:

- L = 11.38 m

- Thickness = 0.55 m

Loads:

[type] [group] [value]

- Presure1 (Fbot) = 29.5e3 Pa

- Presure2 (Fmain)= 25.8e3 Pa

- Presure3 (Ftop) = 24.3e3 Pa

- Presure4 (Fcentre1,Fcentre2)= 182.6e3 Pa

Boundary conditions:

- Lbot (DX=0.0, DY=0.0, DZ=0.0)

- Ltop (DZ=0.0)

Material:

Concrete

- E = 32e9 Pa

- Nu = 0.2

Create all points and lines using: [New Entity]->[Basic}->[Point] and [New Entity]->[Basic]->[Line]

:

:

The coordinates are:

P1 = geompy.MakeVertex( 0.000, 0.00, 0.00) P2 = geompy.MakeVertex( 11.380, 0.00, 0.00) P3 = geompy.MakeVertex( 0.433, 2.25, 0.00) P4 = geompy.MakeVertex( 11.813, 2.25, 0.00) P5 = geompy.MakeVertex( 1.875, 9.75, 0.00) P6 = geompy.MakeVertex( 13.255, 9.75, 0.00) P7 = geompy.MakeVertex( 2.010, 10.45, 0.00) P8 = geompy.MakeVertex( 13.390, 10.45, 0.00)

P9 = geompy.MakeVertex( 5.300, 5.72, 0.00) P10 = geompy.MakeVertex( 5.300, 7.05, 0.00) P11 = geompy.MakeVertex( 9.830, 5.72, 0.00) P12 = geompy.MakeVertex( 9.830, 7.05, 0.00) P13 = geompy.MakeVertex( 5.300, 8.42, 0.00) P14 = geompy.MakeVertex( 5.300, 9.75, 0.00) P15 = geompy.MakeVertex( 9.830, 8.42, 0.00) P16 = geompy.MakeVertex( 9.830, 9.75, 0.00)

Create one big face Ftotal [New Entity]->[Build]->[Face]

Ftotal: Line7,Line6,Line8,Line12,Line11,Line10,Line9,Line1

Create three wires [New Entity]->[Build]->[Wire]

- Wire1: Line3,Line4,Line5

- Wire2: Line17,Line18,Line19

- Wire3: Line13,Line14,Line15,Line16

Create vector [New Entity]->[Basic]->[Vector]

(0,0,1)

Create four extrusions [New Entity]->[Generation]->[Extrusion]

- Extrusion1: Wire1,vz

- Extrusion2: Wire2,vz

- Extrusion3: Wire3,vz

- Extrusion4: Line2,vz

Partitioning of the geometry

Why do we need to partition the geometry? We need geometrical entities or groups for loads and boundary conditions. Partitioning the geometry makes sure that the for resulting mesh each group is meshed along its borders correctly and the mesh is connected between these groups.

Partitioning process: the geometry is divided by planes or other 2D surfaces. These Tool objects need to divide the geometry completely in two seperate parts. In Salome several Tool objects can be chosen in one Partition operation. After the partitioning the groups need to be created. In the Aster command file these groups can be used to define loads, boundary conditions, displacements, stresses, strains etc.

Create partition [Operations]->[Partition]

- Part_main: Ftotal,Extrusion1,Extrusion2,Extrusion3,Extrusion4

Create two groups for boundary conditions [New Entity]->[Group]->[Create]

Shape type: line

Main Shape: Part_main

- Lleft: left lines: Line7,Line8,Line9

- Lright: right lines: Line10,Line11,Line12

Triangle mesh

Set Mesh 1D: Composite Side discretisation

Set Mesh 1D Average lenght: 0,5

Mesh 2D settings: Netgen 2d

Mesh info:

Computed Mesh:

Since we are going to use COQUE_3D elements in the calculation, we need quadratic elements. So we convert the linear to quadratic mesh. If you want to make sure that the midside nodes will be locked to the geometry, you can tick the medium nodes on geometry.

Save the mesh: in the mesh module, right click on the <mesh_name> --> Export to MED file, give file name or accept default (Mesh.med in this case) and <save>. Now the mesh is available for Aster and calculations can be performed.

ASTK - Aster

General way of working

For the calculations we need two input files:

- mesh file, this has been discussed in the previous part

- command file, a list of commands for processing by Aster

Several output files are generated by Aster, look here for more [information]. ASTK is the interface for defining input and output files that are needed by Aster. The mesh file is already available so we are going to discuss the command file now.

The comm files is sequence of commands processed by Aster. In this case the rough outline is:

- read the mesh file

- define material and mechanical properties to the geometrical entities

- define a model

- perform the calculations

- determine the displacements and stresses at the nodes based on the previous step

- write the quantities to a result mesh file

Detailed commands

Reading mesh and applying the model

Here the commands are discussed in detail.

In principle these are a Python commands. Any valid Python expression can be inserted in the command file.

First command is always DEBUT. The initial mesh meshinit is read. This is now a quadratic triangular mesh. Each triangle has 6 nodes: 3 corner nodes and 3 midside nodes. Since we are going to use a COQUE_3D modelisation, that uses 7 nodes for a triangle, we need to convert this mesh to meshmod.

- meshmod <-- meshinit [CREA_MAILLAGE]

To control the orientation of the normals of meshmod we use MODI_MAILLAGE to make sure that normals of all triangles point in the same direction and we can give these normals a dedicated direction.

Based on the meshes mechanical models are built:

- modeinit <-- meshinit <-- 6 nodes triangle [AFFE_MODELE]

- modmod <-- meshmod <-- 7 nodes triangle [AFFE_MODELE]

definition of models

DEBUT();

meshinit=LIRE_MAILLAGE(FORMAT='MED',);

modinit=AFFE_MODELE(MAILLAGE=meshinit,

AFFE=_F(GROUP_MA= ('Fbot','Fmain','Ftop','Fcentre1','Fcentre2',),

PHENOMENE='MECANIQUE',

MODELISATION='3D',),);

meshmod=CREA_MAILLAGE(MAILLAGE=meshinit,

MODI_MAILLE=_F(TOUT='OUI',OPTION='TRIA6_7',),);

meshmod=MODI_MAILLAGE(reuse =meshmod,

MAILLAGE=meshmod,

ORIE_NORM_COQUE=_F(GROUP_MA=('Fbot','Fmain','Ftop','Fcentre1','Fcentre2',),),);

###VECT_NORM= (0,0,+1),NOEUD='N19'),);

modmod=AFFE_MODELE(MAILLAGE=meshmod,

AFFE=_F(TOUT='OUI',

PHENOMENE='MECANIQUE',

MODELISATION='COQUE_3D',),);

shell - mechanical properties

The shell characteristics are not defined in the mesh. So parameters like thickness need to determined here. All the shell characteristics are defined by the AFFE_CARA_ELEM command:

- the model to be used MODELE

- the geometrical parts on which it applies: COQUE=_F(parts)

- thickness EPAIS

- number of layers COQUE_NCOU (one is enough for a linear calculation)

- local coordinate system by VECTEUR=(lx,ly,lz). The projection of this vector on the shell defines the local x axis. The local y axis is perpendicular to the local x axis in the shell plane. The local z axis is -hence- the normal on the plane. Default value is global x axis (1,0,0). This is important for local stresses (SIXX, SIYY, SIZZ, SIXY, SIXZ and SIYZ) and strains.

- offset EXCENTREMENT (not applicable for COQUE_3D modelisation).

th = 0.55

shellch=AFFE_CARA_ELEM(MODELE=modmod,

COQUE=_F(GROUP_MA=('Fbot','Fmain','Ftop','Fcentre1','Fcentre2',),

EPAIS=th,

VECTEUR=(1.0,0.0,0.0,),

COQUE_NCOU=1,

EXCENTREMENT=0.000),);

You can define the material properties by DEFI_MATERIAU

steel=DEFI_MATERIAU(ELAS=_F(E=210000000000.0,

NU=0.3,

RHO=7850.0,),);

concrete=DEFI_MATERIAU(ELAS=_F(E=32000000000.0,

NU=0.2,

RHO=2500.0,),);

The material properties need to applied to the selected parts of the geometry, in this case all parts are selected (TOUT='OUI')

material=AFFE_MATERIAU(MAILLAGE=meshmod,

AFFE=_F(TOUT='OUI',

MATER=concrete,),);

Applying load and boundary conditions on the construction by the command AFFE_CHAR_MECA. The key words are:

- loads are applied to model: MODELE=modmod

- defintion of prescribed displacements by DDL_IMPO applied on several groups

- ... geometrical group: GROUP_MA=(part),

- ... fixed displacement in directions eg DX=DY=DZ=0.00

- apply a pressure on groups: FORCE_COQUE

- ... geometrical group: GROUP_MA=(part),

- ... value of pressue PRES=pressure

load_bc=AFFE_CHAR_MECA(MODELE=modmod,

DDL_IMPO=(_F(GROUP_MA='Lleft',

DX=0.0,

DY=0.0,

DZ=0.0,),

_F(GROUP_MA='Lright',

DZ=0.0,),),

FORCE_COQUE=(_F(GROUP_MA='Fbot',

PRES=29.5e3,),

_F(GROUP_MA='Fmain',

PRES=25.8e3,),

_F(GROUP_MA='Ftop',

PRES=24.3e3,),

_F(GROUP_MA=('Fcentre1','Fcentre2',),

PRES=182.6e3,),),);

static calculation

resu=MECA_STATIQUE(MODELE=modmod,

CHAM_MATER=material,

CARA_ELEM=shellch,

EXCIT=_F(CHARGE=load_bc,),

OPTION='SIEF_ELGA_DEPL',);

determine element and nodel properties

resu=CALC_ELEM(reuse =resu,

MODELE=modmod,

CHAM_MATER=material,

RESULTAT=resu,

REPE_COQUE=_F(NIVE_COUCHE='SUP',),

OPTION='SIGM_ELNO_DEPL',);

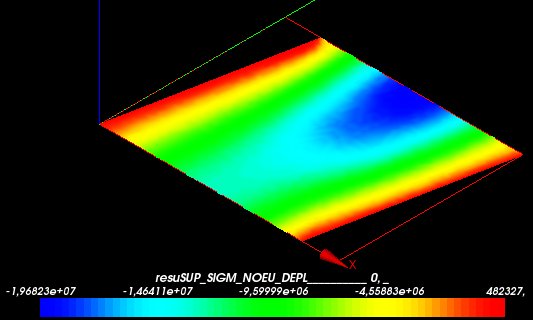

determine stress at outer layer

resuSUP=CALC_ELEM(MODELE=modmod,

CHAM_MATER=material,

RESULTAT=resu,

REPE_COQUE=_F(NIVE_COUCHE='SUP',),

OPTION=('SIGM_ELNO_DEPL','EQUI_ELNO_SIGM',),);

resuSUP=CALC_NO(reuse =resuSUP,

RESULTAT=resuSUP,

OPTION=('SIGM_NOEU_DEPL','EQUI_NOEU_SIGM',),);

IMPR_RESU(MODELE=modmod,

FORMAT='MED',

UNITE=80,

RESU=(_F(MAILLAGE=meshmod,

RESULTAT=resu,

NOM_CHAM='DEPL',),

_F(MAILLAGE=meshmod,

RESULTAT=resuSUP,

NOM_CHAM=('SIGM_NOEU_DEPL','EQUI_NOEU_SIGM',),),),);

FIN();

Shell6.comm.zip http://www.caelinux.org/wiki/images/e/e4/Shell6.comm.zip - obsolete: bad bc

Postprocessing

displacements

- Deformed shape

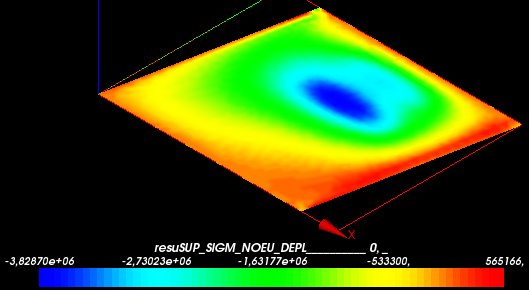

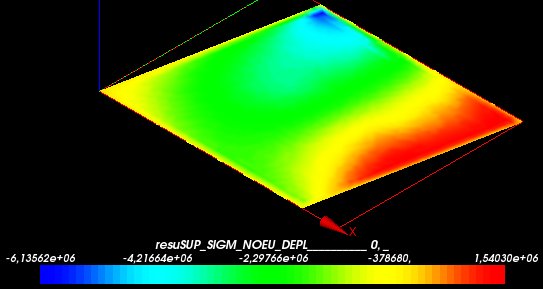

Local stresses

- SIXX

- SIYY

- SIXY

Reactions forces

For the load case:

load_bc=AFFE_CHAR_MECA(MODELE=modmod,

DDL_IMPO=(_F(GROUP_MA=('Lleft',),

DX=0.0,

DY=0.0,

DZ=0.0,),

_F(GROUP_MA='Lright',

DZ=0.0,),),

FORCE_COQUE=(_F(GROUP_MA=('Fcentre1','Fcentre2'),PRES=182.6e3,),

_F(GROUP_MA=('Ftop' ),PRES=24.3e3,),

_F(GROUP_MA=('Fbot' ),PRES=29.5e3,),

_F(GROUP_MA=('Fmain'),PRES=25.8e3,),),);

### added for nodal forces and reaction forces

resu=CALC_NO(reuse =resu,

RESULTAT=resu,

OPTION= ('FORC_NODA','REAC_NODA',),);

....

In the command DEFI_GROUP groups of nodes [GROUP_NO] 'Nleft' and 'Nright' are created from the geometrical defined edges [GROUP_MA] 'Lleft' and 'Lright'. Later on they are united into a group of nodes 'Nsupport' by UNION. This is required because the creation of a table by POST_RELEVE_T needs a group of nodes.

meshmod=DEFI_GROUP(reuse =meshmod,

MAILLAGE=meshmod,

CREA_GROUP_NO=(_F(NOM='Nleft',GROUP_MA=('Lleft',),),

_F(NOM='Nright',GROUP_MA=('Lright',),),),);

meshmod=DEFI_GROUP(reuse =meshmod,

MAILLAGE=meshmod,

CREA_GROUP_NO=_F(NOM='Nsupport',UNION=('Nleft','Nright',),),);

Now determine a table for nodal reaction forces TB_nodf. The values are stored in REAC_NODA and FORC_NODA fields (champ). The forces are determined on the supported area Nsupport. The table is actually written to a file by IMPR_TABLE.

TB_nodf=POST_RELEVE_T(ACTION=(_F(OPERATION='EXTRACTION',

INTITULE='ReactionForces',

RESULTAT=resu,

NOM_CHAM='REAC_NODA',

TOUT_ORDRE='OUI',

GROUP_NO='Nsupport',

RESULTANTE=('DX','DY','DZ',),

MOYE_NOEUD='NON',),

_F(OPERATION='EXTRACTION',

INTITULE='NodalForces',

RESULTAT=resu,

NOM_CHAM='FORC_NODA',

TOUT_ORDRE='OUI',

GROUP_NO='Nsupport',

RESULTANTE=('DX','DY','DZ',),

MOYE_NOEUD='NON',),

_F(OPERATION='EXTRACTION',

INTITULE='moments',

RESULTAT=resu,

NOM_CHAM='FORC_NODA',

GROUP_NO='Nsupport',

RESULTANTE=('DX','DY','DZ',),

MOMENT=('DRX','DRY','DRZ',),

POINT=(0.0,0.0,0.0,),),),

TITRE='Reactions',);

IMPR_TABLE(TABLE=TB_nodf,

FORMAT='TABLEAU',

UNITE=26,

SEPARATEUR=' * ',

TITRE='reaction forces at nodes on group Nsupport');

The reaction and nodal forces on the supporting edges are:

[loads * areas: 24.3 * 7.966 + 182.6 * 6.0249 * 2 + 25.8 * 73.3 + 29.5 * 25.605 = 5040.4 kN = 5.040E+06 N]

#quantities at edges - nodes Nsupport #Reactions * INTITULE * RESU * NOM_CHAM * NUME_ORDRE * INST * DX * DY * DZ * RESULT_X * RESULT_Y * RESULT_Z * MOMENT_X * MOMENT_Y * MOMENT_Z * ReactionForces * resu * REAC_NODA * 1 * 0.00000E+00 * -1.35387E-08 * 2.63751E-08 * 5.04036E+06 * - * - * - * - * - * - * NodalForces * resu * FORC_NODA * 1 * 0.00000E+00 * -1.35387E-08 * 2.63751E-08 * 4.90339E+06 * - * - * - * - * - * - * moments * resu * REAC_NODA * 1 * 0.00000E+00 * - * - * - * -1.35387E-08 * 2.63751E-08 * 5.04036E+06 * 3.06316E+07 * -3.53025E+07 * 2.91360E-07 * moments * resu * REAC_NODA * 1 * 0.00000E+00 * - * - * - * -1.35387E-08 * 2.63751E-08 * 5.04036E+06 * 1.91375E+01 * 1.05470E+01 * 2.43516E-08

Note:

The last row is created by changing the point POINT to POINT=(xc,yc,zc)=(7.003964,6.077264,0.0,) yields the following -nearly zero- moments. [xc=My/Freactz, yc=-Mx/Freactz]. This means that my calculator is still alright.

In stead of the resultant reaction force you can also write the reaction force at each node to a file. Use NOM_CMP=(...,'DZ') to replace RESULTANTE=(...,'DZ') in the previous command:

TB_nodf=POST_RELEVE_T(ACTION=_F(OPERATION='EXTRACTION',

INTITULE='ReactionForces',

RESULTAT=resu,

NOM_CHAM='REAC_NODA',

TOUT_ORDRE='OUI',

GROUP_NO='Nsupport',

NOM_CMP='DZ',

MOYE_NOEUD='NON',),

INFO=2,

TITRE='reaction forces - z at all nodes',);

And the result:

#quantities at edges - nodes Nsupport #reaction forces - z at all nodes * INTITULE * NOEUD * RESU * NOM_CHAM * NUME_ORDRE * INST * ABSC_CURV * COOR_X * COOR_Y * COOR_Z * DZ * ReactionForces * N27 * resu * REAC_NODA * 1 * 0.00000E+00 * 0.00000E+00 * 1.42861E+00 * 7.42875E+00 * 0.00000E+00 * 3.12903E+05 * ReactionForces * N31 * resu * REAC_NODA * 1 * 0.00000E+00 * 5.27364E+00 * 4.32692E-01 * 2.25000E+00 * 0.00000E+00 * 1.42424E+05 * ReactionForces * N48 * resu * REAC_NODA * 1 * 0.00000E+00 * 1.32675E+01 * 1.94231E+00 * 1.01000E+01 * 0.00000E+00 * 2.46064E+05 * ReactionForces * N56 * resu * REAC_NODA * 1 * 0.00000E+00 * 2.01959E+01 * 6.33894E-01 * 3.29625E+00 * 0.00000E+00 * 2.05100E+05 * ReactionForces * N67 * resu * REAC_NODA * 1 * 0.00000E+00 * 2.24069E+01 * 2.16346E-01 * 1.12500E+00 * 0.00000E+00 * 1.69819E+05 * ReactionForces * N110 * resu * REAC_NODA * 1 * 0.00000E+00 * 2.56834E+01 * 8.35096E-01 * 4.34250E+00 * 0.00000E+00 * 1.50752E+05 * ReactionForces * N182 * resu * REAC_NODA * 1 * 0.00000E+00 * 3.11900E+01 * 1.87500E+00 * 9.75000E+00 * 0.00000E+00 * 9.09171E+04 * ReactionForces * N193 * resu * REAC_NODA * 1 * 0.00000E+00 * 3.45733E+01 * 1.23606E+00 * 6.42750E+00 * 0.00000E+00 * 7.97917E+04 * ReactionForces * N208 * resu * REAC_NODA * 1 * 0.00000E+00 * 3.72846E+01 * 1.74808E+00 * 9.09000E+00 * 0.00000E+00 * 1.75635E+05 * ReactionForces * N210 * resu * REAC_NODA * 1 * 0.00000E+00 * 4.10575E+01 * 1.03558E+00 * 5.38500E+00 * 0.00000E+00 * 2.74874E+05 * ReactionForces * N270 * resu * REAC_NODA * 1 * 0.00000E+00 * 4.41583E+01 * 1.62115E+00 * 8.43000E+00 * 0.00000E+00 * 1.25480E+05 * ReactionForces * N271 * resu * REAC_NODA * 1 * 0.00000E+00 * 5.27428E+01 * 0.00000E+00 * 0.00000E+00 * 0.00000E+00 * 5.27529E+04 * ReactionForces * N290 * resu * REAC_NODA * 1 * 0.00000E+00 * 6.33843E+01 * 2.00962E+00 * 1.04500E+01 * 0.00000E+00 * 4.29332E+05 * ReactionForces * N9 * resu * REAC_NODA * 1 * 0.00000E+00 * 7.67582E+01 * 1.15963E+01 * 1.12500E+00 * 0.00000E+00 * 1.92612E+05 * ReactionForces * N40 * resu * REAC_NODA * 1 * 0.00000E+00 * 8.55412E+01 * 1.32550E+01 * 9.75000E+00 * 0.00000E+00 * 6.59317E+04 * ReactionForces * N50 * resu * REAC_NODA * 1 * 0.00000E+00 * 9.54698E+01 * 1.13800E+01 * 0.00000E+00 * 0.00000E+00 * 2.57970E+05 * ReactionForces * N81 * resu * REAC_NODA * 1 * 0.00000E+00 * 1.00006E+02 * 1.22367E+01 * 4.45500E+00 * 0.00000E+00 * 1.64125E+05 * ReactionForces * N119 * resu * REAC_NODA * 1 * 0.00000E+00 * 1.01129E+02 * 1.20247E+01 * 3.35250E+00 * 0.00000E+00 * 2.92612E+05 * ReactionForces * N126 * resu * REAC_NODA * 1 * 0.00000E+00 * 1.02252E+02 * 1.18127E+01 * 2.25000E+00 * 0.00000E+00 * 1.88369E+05 * ReactionForces * N152 * resu * REAC_NODA * 1 * 0.00000E+00 * 1.10602E+02 * 1.33896E+01 * 1.04500E+01 * 0.00000E+00 * 8.85387E+04 * ReactionForces * N161 * resu * REAC_NODA * 1 * 0.00000E+00 * 1.14469E+02 * 1.26593E+01 * 6.65250E+00 * 0.00000E+00 * 1.28900E+05 * ReactionForces * N206 * resu * REAC_NODA * 1 * 0.00000E+00 * 1.15588E+02 * 1.24480E+01 * 5.55375E+00 * 0.00000E+00 * 3.91612E+05 * ReactionForces * N209 * resu * REAC_NODA * 1 * 0.00000E+00 * 1.20218E+02 * 1.33223E+01 * 1.01000E+01 * 0.00000E+00 * 1.63694E+05 * ReactionForces * N241 * resu * REAC_NODA * 1 * 0.00000E+00 * 1.22701E+02 * 1.28533E+01 * 7.66125E+00 * 0.00000E+00 * 3.70568E+05 * ReactionForces * N243 * resu * REAC_NODA * 1 * 0.00000E+00 * 1.23728E+02 * 1.30473E+01 * 8.67000E+00 * 0.00000E+00 * 1.13136E+05 * ReactionForces * N304 * resu * REAC_NODA * 1 * 0.00000E+00 * 1.24278E+02 * 1.31512E+01 * 9.21000E+00 * 0.00000E+00 * 1.66448E+05

To write to reaction forces to a med file and display them in Salome you can use:

IMPR_RESU(UNITE=80,

FORMAT='MED',

MODELE=modmod,

RESU=(_F(MAILLAGE=meshmod,

RESULTAT=resu,

NOM_CHAM=('REAC_NODA',),),),);

Note the the pressures have reversed sign here for nicer visual effect.

Extraction of maximum displacements and stresses

The OPERATION='EXTREMA' calculates the MIN, MAX, MIN_ABS, MAX_ABS values of a requested field on the geometrical area.

See http://www.code-aster.org/V2/doc/v9/man_u/u4/u4.81.21.pdf

TB_nodf=POST_RELEVE_T(ACTION=(_F(OPERATION='EXTREMA',

INTITULE='displacements dz',

RESULTAT=resu,

NOM_CHAM='DEPL',

TOUT_ORDRE='OUI',

GROUP_NO='Nsupport',

NOM_CMP='DZ',),

_F(OPERATION='EXTREMA',

INTITULE='equiss NOEU',

RESULTAT=resuSUP,

NOM_CHAM='EQUI_NOEU_SIGM',

TOUT_ORDRE='OUI',

GROUP_NO='Nsupport',

NOM_CMP=('VMIS','TRESCA','PRIN_1','PRIN_2','PRIN_3',),),

_F(OPERATION='EXTREMA',

INTITULE='equiss ELNO',

RESULTAT=resuSUP,

NOM_CHAM='EQUI_ELNO_SIGM',

TOUT_ORDRE='OUI',

GROUP_NO='Nsupport',

NOM_CMP=('VMIS','TRESCA','PRIN_1','PRIN_2','PRIN_3',),),

_F(OPERATION='EXTREMA',

INTITULE='local stresses',

RESULTAT=resuSUP,

NOM_CHAM='SIGM_NOEU_DEPL',

TOUT_ORDRE='OUI',

GROUP_NO='Nsupport',

NOM_CMP=('SIXX','SIYY','SIXY',),),),

INFO=2,

TITRE='Min/max of displacement DZ - stresses',);

#extreme displacements on group allnodes #Min/max of displacement DZ - stresses * INTITULE * RESU * NOM_CHAM * NUME_ORDRE * EXTREMA * MAILLE * NOEUD * CMP * VALE * displacements dz * resu * DEPL * 1 * MAX * - * N241 * DZ * 1.94659E-19 * displacements dz * resu * DEPL * 1 * MIN * - * N115 * DZ * -2.91659E-02 * displacements dz * resu * DEPL * 1 * MAX_ABS * - * N115 * DZ * 2.91659E-02 * displacements dz * resu * DEPL * 1 * MIN_ABS * - * N152 * DZ * 4.74802E-22

* equiss NOEU * resuSUP * EQUI_NOEU_SIGM * 1 * MAX * - * N107 * TRESCA * 1.99754E+07 * equiss NOEU * resuSUP * EQUI_NOEU_SIGM * 1 * MIN * - * N182 * PRIN_1 * -3.00400E+06 * equiss NOEU * resuSUP * EQUI_NOEU_SIGM * 1 * MAX_ABS * - * N107 * TRESCA * 1.99754E+07 * equiss NOEU * resuSUP * EQUI_NOEU_SIGM * 1 * MIN_ABS * - * N35 * PRIN_2 * 1.32964E+03

* equiss ELNO * resuSUP * EQUI_ELNO_SIGM * 1 * MAX * M204 * N107 * TRESCA * 2.02489E+07 * equiss ELNO * resuSUP * EQUI_ELNO_SIGM * 1 * MIN * M125 * N123 * PRIN_1 * -6.08974E+06 * equiss ELNO * resuSUP * EQUI_ELNO_SIGM * 1 * MAX_ABS * M204 * N107 * TRESCA * 2.02489E+07 * equiss ELNO * resuSUP * EQUI_ELNO_SIGM * 1 * MIN_ABS * M69 * NS1 * VMIS * 0.00000E+00

* local stresses * resuSUP * SIGM_NOEU_DEPL * 1 * MAX * - * N107 * SIXX * 1.97055E+07 * local stresses * resuSUP * SIGM_NOEU_DEPL * 1 * MIN * - * N81 * SIXY * -9.99157E+05 * local stresses * resuSUP * SIGM_NOEU_DEPL * 1 * MAX_ABS * - * N107 * SIXX * 1.97055E+07 * local stresses * resuSUP * SIGM_NOEU_DEPL * 1 * MIN_ABS * - * N250 * SIYY * 1.87510E+04

Note that the minimum and maximum values of the local stresses are taken over the complete group denoted by the NOM_CMP=('VMIS','TRESCA','PRIN_1','PRIN_2','PRIN_3',)

So if you want the minimum and maximum values seperately, take only one component for each extration of the extreme values, eg; NOM_CMP='DZ'

.....

.....