Difference between revisions of "Contrib:KeesWouters/Homard/lshape/loop"

Keeswouters (Talk | contribs) m |

Keeswouters (Talk | contribs) m (→Remarks on Python language) |

||

| (77 intermediate revisions by 6 users not shown) | |||

| Line 3: | Line 3: | ||

['''under construction - just started 2010-02-22 ... '''] | ['''under construction - just started 2010-02-22 ... '''] | ||

| − | This contribution is based on the mesh refinement described [http://www.caelinux.org/wiki/index.php/Contrib:KeesWouters/Homard/lshape here] | + | This contribution is based on the mesh refinement described [http://www.caelinux.org/wiki/index.php/Contrib:KeesWouters/Homard/lshape here]. Two mesh refinements based on three calculations are given there. Since the three calculations are basically the same, it is convenient to use the Python looping facility. So now we will perform four calculations and three mesh refinements. The iteration is controlled by the a Python for loop. |

=='''The geometry'''== | =='''The geometry'''== | ||

==='''The geometry and the mesh of the construction'''=== | ==='''The geometry and the mesh of the construction'''=== | ||

The mesh refinement is based on [http://www.code-aster.org/outils/homard Homard]. | The mesh refinement is based on [http://www.code-aster.org/outils/homard Homard]. | ||

| − | As usual the geometry is quite simple | + | As usual the geometry is quite simple and is defined in the link given above. |

| − | + | ||

| − | + | ||

: [[image:kw_lshape.jpg]] <br> | : [[image:kw_lshape.jpg]] <br> | ||

| − | + | Again, the mesh consists of coarse, tetrehedral elements to start with. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | The | + | ==='''The load of the construction'''=== |

| + | The L shape is fixed in all directions at the bottom area Afix. The area at opposite end of L is denoted Apres. For simplicity, on this area a displacement of 0.1 mm is given in the y direction. | ||

| − | + | =='''The refinement process'''== | |

| − | The | + | The general idea of the Homard refinement is to start with a rather course mesh and update the mesh according to a criterium. In this case we use the stress error estimate ''ERRE_ELEM_SIGM'' and its component ''ERREST''. For more details on this error estimation see [[http://www.code-aster.org/V2/doc/default/man_u/u7/u7.03.01.pdf U7.03.01.pdf] Homard]. To start a standard load case will be calculated and an error estimation on all the elements will be carried out. In this example a percentage of the elements with the highest error estimates will be refined. |

| + | A new calculation with the adapted mesh will then follow. For this calculation all the models, loads and parameters need to be rebuild. So it is most suitable to define geometrical entities ''(GROUP_MA)'' in the mesh in stead of nodes. | ||

| − | + | Notes: | |

| − | + | When using Homard it is: | |

| − | + | * quite impractical to use group of nodes (because they will be renumbered or reallocated) | |

| + | * not possible to use ''poursuite'' | ||

To summarise: | To summarise: | ||

| Line 33: | Line 31: | ||

* define material properties | * define material properties | ||

* define number of refinement iterations (whether or not fixed) | * define number of refinement iterations (whether or not fixed) | ||

| − | + | * for counter in range: | |

| − | * | + | ** define model |

| − | * | + | ** apply material to model |

| − | * | + | ** apply load to model |

| − | * | + | ** perform calculation |

| − | * | + | ** determine element and node parameters |

| − | * | + | ** (write output data) |

| − | * | + | ** refinement of mesh MACR_ADAP_MAIL [no need for refinement in the last iteration] |

| − | * | + | |

The error estimation is determined in the CALC_ELEM command, by the option 'ERRE_ELEM_SIGM': | The error estimation is determined in the CALC_ELEM command, by the option 'ERRE_ELEM_SIGM': | ||

| Line 48: | Line 45: | ||

The refinement command itself is as follows: | The refinement command itself is as follows: | ||

| − | + | ...... | |

| − | + | print mesh | |

| − | + | print model | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | counterp1 = counter+1; | |

| + | meshcp1=CO('mesh_%d' %counterp1) | ||

| + | MACR_ADAP_MAIL(MAILLAGE_N=mesh[counter], | ||

| + | MAILLAGE_NP1=meshcp1, | ||

| + | ADAPTATION='RAFFINEMENT', | ||

| + | RESULTAT_N=result[counter], | ||

| + | INDICATEUR='ERRE_ELEM_SIGM', | ||

| + | NOM_CMP_INDICA='ERREST', | ||

| + | CRIT_RAFF_PE=0.20, | ||

| + | QUALITE='OUI', | ||

| + | CONNEXITE='OUI', | ||

| + | TAILLE='OUI', | ||

| + | LANGUE ='ANGLAIS'); | ||

| + | mesh[counter+1] = meshcp1; | ||

| − | |||

| − | |||

| − | == | + | The command takes the current mesh ''mesh[counter]'' as input '''MAILLAGE_N=curmesh''' and the output mesh is '''MAILLAGE_NP1=meshcp1'''. Again, the meshcp1 is not defined (in the Python sense) so we need to use the CO('..') operator on forehand: |

| − | + | counterp1 = counter+1; | |

| + | meshcp1=CO('mesh_%d' %counterp1) | ||

| + | |||

| + | Further keywords are the ADAPTATION='RAFFINEMENT' together with CRIT_RAFF_PE=0.10. In this case the 0.10 or 10 % of the elements with the largest error estimate (based on stress error indicator INDICATEUR='ERRE_ELEM_SIGM', NOM_CMP_INDICA='ERREST') are refined. The other elements remain untouched. | ||

| + | At the end we need to assign the next element of array mesh to the newly defined meshcp1: mesh[counter+1] = meshcp1. | ||

| + | In the last iteration no refinement is required, hence the if statement. | ||

| + | |||

| + | Note: | ||

| + | I mainly based this command file on the astest example zzzz121a.comm (see links below). In that case the statement immediately after macro command MACR_ADAP_MAIL mesh[counter+1] = meshcp1 is not included. For my examples it doesnot work without this. | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | ==='''The initialisation of the calculation'''=== | ||

| + | Here the initialisation commands that can be left out the for loop are described: | ||

DEBUT(); | DEBUT(); | ||

| − | # | + | # initialise counters |

| − | + | count = [0,1,2,3]; | |

| + | count0 = count[0]; | ||

| − | # | + | # initialise model parameters |

| − | + | mesh=[None]*4 | |

| − | + | model=[None]*4 | |

| + | Amat=[None]*4 | ||

| + | result=[None]*4 | ||

| + | Load=[None]*4 | ||

#Define material properties | #Define material properties | ||

steel=DEFI_MATERIAU(ELAS=_F(E=2.1e5,NU=.28,),); | steel=DEFI_MATERIAU(ELAS=_F(E=2.1e5,NU=.28,),); | ||

| − | # | + | #Read MED mesh file |

| − | + | mesh[count0]=LIRE_MAILLAGE(UNITE=20,FORMAT='MED',NOM_MED='mesh0',); | |

| − | # define boundary conditions and loads | + | |

| − | + | In the array count all the loop numbers 0 to 3 are defined. This is used to control the for loop. The array parameters mesh, model, Amat, result and Load are initialised with maximum size according to the ''count'' array. | |

| + | Furthermore teh material properties are defined and the initial mesh is read. | ||

| + | |||

| + | ==='''The for loop construction'''=== | ||

| + | |||

| + | |||

| + | # start counter | ||

| + | for counter in count: | ||

| + | model[counter]=AFFE_MODELE(MAILLAGE=mesh[counter],AFFE=_F(TOUT='OUI', | ||

| + | PHENOMENE='MECANIQUE',MODELISATION='3D',),); | ||

| + | |||

| + | |||

| + | #Assign material to mesh | ||

| + | Amat[counter]=AFFE_MATERIAU(MAILLAGE=mesh[counter], | ||

| + | AFFE=_F(TOUT='OUI',MATER=steel,),); | ||

| + | |||

| + | #define boundary conditions and loads | ||

| + | Load[counter]=AFFE_CHAR_MECA(MODELE=model[counter], | ||

DDL_IMPO=(_F(GROUP_MA='Afix',DX=0.0,DY=0.0,DZ=0.0,), | DDL_IMPO=(_F(GROUP_MA='Afix',DX=0.0,DY=0.0,DZ=0.0,), | ||

_F(GROUP_MA='Apres',DX=0.0,DY=0.1,DZ=0.0,),),); | _F(GROUP_MA='Apres',DX=0.0,DY=0.1,DZ=0.0,),),); | ||

| − | + | result[counter]=MECA_STATIQUE(MODELE=model[counter], | |

| − | + | CHAM_MATER=Amat[counter], | |

| − | + | EXCIT=(_F(CHARGE=Load[counter],),),); | |

| − | + | result[counter]=CALC_ELEM(reuse =result[counter], | |

| − | TOUT='OUI',TYPE_OPTION='TOUTES', | + | MODELE=model[counter], |

| + | RESULTAT=result[counter], | ||

| + | TOUT='OUI', | ||

| + | TYPE_OPTION='TOUTES', | ||

OPTION=('EQUI_ELNO_SIGM','SIEF_ELNO_ELGA','ERRE_ELEM_SIGM',),); | OPTION=('EQUI_ELNO_SIGM','SIEF_ELNO_ELGA','ERRE_ELEM_SIGM',),); | ||

| − | + | result[counter]=CALC_NO(reuse =result[counter], | |

| + | RESULTAT=result[counter], | ||

| + | OPTION=('EQUI_NOEU_SIGM',),); | ||

| − | + | unitnumber = 80 | |

| − | + | IMPR_RESU(FORMAT='MED', | |

| + | UNITE=unitnumber, | ||

| + | RESU=_F(MAILLAGE=mesh[counter],RESULTAT=result[counter],NOM_CHAM=('DEPL',),),); | ||

| − | |||

| − | |||

| − | + | ##========================## | |

| − | + | ## define mesh refinement ## | |

| + | ##========================## | ||

| + | if (counter<count[len(count)-1]): | ||

| + | print count, len(count), count[len(count)-1], counter | ||

| + | print mesh | ||

| + | print model | ||

| + | |||

| + | counterp1 = counter+1; | ||

| + | meshcp1=CO('mesh_%d' %counterp1) | ||

| + | MACR_ADAP_MAIL(MAILLAGE_N=mesh[counter], | ||

| + | LANGUE='ENGLISH', | ||

| + | MAILLAGE_NP1=meshcp1, | ||

ADAPTATION='RAFFINEMENT', | ADAPTATION='RAFFINEMENT', | ||

| − | RESULTAT_N= | + | RESULTAT_N=result[counter], |

INDICATEUR='ERRE_ELEM_SIGM', | INDICATEUR='ERRE_ELEM_SIGM', | ||

NOM_CMP_INDICA='ERREST', | NOM_CMP_INDICA='ERREST', | ||

| − | CRIT_RAFF_PE=0. | + | CRIT_RAFF_PE=0.10, |

QUALITE='OUI', | QUALITE='OUI', | ||

CONNEXITE='OUI', | CONNEXITE='OUI', | ||

TAILLE='OUI',); | TAILLE='OUI',); | ||

| − | + | mesh[counter+1] = meshcp1; | |

| − | + | #endif | |

| + | #end for loop | ||

| − | + | And close the calculations: | |

| − | + | FIN(FORMAT_HDF='OUI',); | |

| − | + | ||

| + | All the results are now written to a single file on unit 80. In Salome's object browser the results are available after 'file' --> 'import'--> '<resultfile>.med' under mesh_0, mesh_1, mesh_2 and mesh_2. Each mesh contains a ''DEPL'' under ''fields''. By adding the LANGUE='ENGLISH' Homard's output will be in English! One small portion of text output that will be easier to understand for non-Fr users. | ||

| − | + | ===''Remarks on Python language''=== | |

| − | + | First note that 'test_%d',%3 will evaluate to 'test_3' in Python. | |

| + | Now suppose counter=1, counterp1=2 then meshcp1 evaluates to '' 'mesh_2' = CO('mesh_2')''. The new name 'mesh_2' is defined. This corresponds to mesh[2]. | ||

| + | * Note that the name 'mesh_2' has maximum length of 8 characters, due to (Fortran?) filename limitations. | ||

| − | |||

| − | |||

| − | + | To check this the print commands ''print model'' and ''print mesh'' have been added at the start of this block. The output of these commands are e.g: | |

| − | + | ||

| − | + | ||

| − | |||

| − | + | ''print mesh'',''print model'',.....:<br> | |

| − | + | ||

| − | + | ||

| − | + | [<maillage_sdaster(72a5fd0,'mesh_0 ')>, <maillage_sdaster(56ed650,'mesh_1 ')>, None , None] | |

| − | + | [<modele_sdaster(72becd0,'model_0 ')>, <modele_sdaster(56ed750,'model_1 ')>, None , None] | |

| + | [<char_meca(5af3110,'Load_0 ')>, <char_meca(56fa6d0,'Load_1 ')>, None , None] | ||

| + | [<cham_mater(5661fd0,'Amat_0 ')>, <cham_mater(56eb290,'Amat_1 ')>, None , None] | ||

| + | [<evol_elas(56e49d0,'result_0 ')>, <evol_elas(56ff690,'result_1 ')>, None , None]<br> | ||

| − | + | '''Command control'''<br> | |

| − | + | The Python for loop is controlled by indenting the commands by a fixed number of characters: | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | maxcount = 4; | |

| − | + | for counter in range(0,maxcount): | |

| − | + | do_something(); | |

| − | + | if (counter<maxcount-1): | |

| − | + | refine(); | |

| − | + | else: | |

| + | donotrefine_or_donothing(); | ||

| + | #endif | ||

| + | #endfor | ||

| − | + | The range command yields: | |

| − | + | maxcount=4; | |

| + | xx = range(0,maxcount);xx | ||

| + | --> xx=[0,1,2,3] | ||

| − | + | =='''The results of the refinement'''== | |

| − | + | ===''Some numerical results''=== | |

| + | The numbers of nodes and quadratic elements (tetrahedrons) of the meshes: | ||

| − | + | 10% 90% new change | |

| − | + | nodes elements changed unchanged elements factor | |

| − | + | 4224 2064 206 1858 | |

| + | 8796 4958 496 4462 3100 15 (= 3100/ 206) | ||

| + | 20043 12029 1203 10826 7567 15 (= 7567/ 496) | ||

| + | 45066 28347 2835 25512 17521 15 (=17521/1203) | ||

| − | + | So, from a single tetrahedron that is refined, 15 tetrahedrons are generated for this mesh. | |

| − | + | In an extended calculation, where the number of refinements are increased to five, the following information is reported in the mess file: | |

| − | + | ||

| − | + | ||

| − | + | elements niveau-----------------------------------level | |

| + | nodes total 0 1 2 3 4 5 | ||

| + | mesh_0 4224 2064 2064 - - - - - | ||

| + | mesh_1 8796 4958 1290 3668 - - - - | ||

| + | mesh_2 20043 12029 496 8757 2776 - - - | ||

| + | mesh_3 45066 28347 69 11727 12259 4292 - - | ||

| + | mesh_4 112313 72762 21 6940 50452 8241 7108 - | ||

| + | mesh_5 272204 180412 0 2132 93176 55159 14843 15066 | ||

| − | + | Hence after 6 iterations, all the elements have been refined, number of level 0 elements is 0. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| + | ===''Some graphical results''=== | ||

In the graph below, the original mesh (top left) and the two successive refinements based on the discussed criteria are depicted (bottom right last iteration). | In the graph below, the original mesh (top left) and the two successive refinements based on the discussed criteria are depicted (bottom right last iteration). | ||

: [[image:kw_refinement_4.jpg]] <br> | : [[image:kw_refinement_4.jpg]] <br> | ||

| − | The picture below shows the stress error estimation 'ERREST'. The first refinement is based on this field | + | The picture below shows the stress error estimation 'ERREST'. The first refinement from mesh0 to mesh1 is based on this ERREST field. |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

=='''The ASTK input files'''== | =='''The ASTK input files'''== | ||

The picture below shows the input and output files defined in ASTK. | The picture below shows the input and output files defined in ASTK. | ||

| − | : [[image: | + | : [[image:kw_astk_loop4.png]] <br> |

=='''Download files'''== | =='''Download files'''== | ||

| − | : [[Media: | + | : [[Media:kw_meshrefine_loop.zip]]<br/> |

This zip contains the following files | This zip contains the following files | ||

* python geometry and mesh files (load in Salome by ''File --> Load script'' (cntrl T)) and right select ''refresh'' (F5) in the object browser). Export the med file in the mesh module under ''mesh0.med'' for further processing by Code-Aster, controlled by ASTK. | * python geometry and mesh files (load in Salome by ''File --> Load script'' (cntrl T)) and right select ''refresh'' (F5) in the object browser). Export the med file in the mesh module under ''mesh0.med'' for further processing by Code-Aster, controlled by ASTK. | ||

| Line 222: | Line 259: | ||

* export file, generated by ASTK. | * export file, generated by ASTK. | ||

| − | The result | + | The result file ''resx0.med'' can be viewed in the post processor module of Salome by ''File --> Import --> resix.med'' or cntrl I in the object browser. Importing it into the mesh module can be useful to check e.g. the number of elements. All the results of the meshes are stored in separate fields ''mesh_0, mesh_1, mesh_2 and mesh_3''. |

| − | + | ||

=='''Links'''== | =='''Links'''== | ||

| Line 229: | Line 265: | ||

pdf file: http://www.code-aster.org/V2/doc/default/man_u/u7/u7.03.01.pdf<br> | pdf file: http://www.code-aster.org/V2/doc/default/man_u/u7/u7.03.01.pdf<br> | ||

Homard website: http://www.code-aster.org/outils/homard | Homard website: http://www.code-aster.org/outils/homard | ||

| + | |||

| + | *It seems I have to update all pdf links; for now check u7.03.01.pdf by hand on the Code Aster site. | ||

| + | |||

| + | Not really links, but nice to study are the examples<br> | ||

| + | * zzzz121a.comm, | ||

| + | * zzzz121b.comm, | ||

| + | * zzzz121c.comm, | ||

| + | * zzzz121d.comm and | ||

| + | * zzzz121e.comm. | ||

| + | in the astest directory [$ASTER_ROOT]/STA[$VERSION]/astest/.....,<br> | ||

| + | e.g in my case: /cae/aster101/STA10.1/astest/zzzz121a.comm | ||

That's it for now.<br> | That's it for now.<br> | ||

Kees | Kees | ||

Latest revision as of 19:43, 7 January 2018

Contents

Mesh refinement using Python loop facility

[under construction - just started 2010-02-22 ... ]

This contribution is based on the mesh refinement described here. Two mesh refinements based on three calculations are given there. Since the three calculations are basically the same, it is convenient to use the Python looping facility. So now we will perform four calculations and three mesh refinements. The iteration is controlled by the a Python for loop.

The geometry

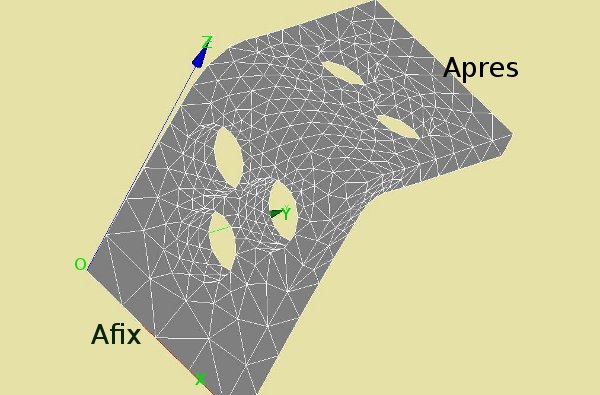

The geometry and the mesh of the construction

The mesh refinement is based on Homard. As usual the geometry is quite simple and is defined in the link given above.

Again, the mesh consists of coarse, tetrehedral elements to start with.

The load of the construction

The L shape is fixed in all directions at the bottom area Afix. The area at opposite end of L is denoted Apres. For simplicity, on this area a displacement of 0.1 mm is given in the y direction.

The refinement process

The general idea of the Homard refinement is to start with a rather course mesh and update the mesh according to a criterium. In this case we use the stress error estimate ERRE_ELEM_SIGM and its component ERREST. For more details on this error estimation see [U7.03.01.pdf Homard]. To start a standard load case will be calculated and an error estimation on all the elements will be carried out. In this example a percentage of the elements with the highest error estimates will be refined. A new calculation with the adapted mesh will then follow. For this calculation all the models, loads and parameters need to be rebuild. So it is most suitable to define geometrical entities (GROUP_MA) in the mesh in stead of nodes.

Notes: When using Homard it is:

- quite impractical to use group of nodes (because they will be renumbered or reallocated)

- not possible to use poursuite

To summarise:

- initial some parameters

- read initial mesh

- define material properties

- define number of refinement iterations (whether or not fixed)

- for counter in range:

- define model

- apply material to model

- apply load to model

- perform calculation

- determine element and node parameters

- (write output data)

- refinement of mesh MACR_ADAP_MAIL [no need for refinement in the last iteration]

The error estimation is determined in the CALC_ELEM command, by the option 'ERRE_ELEM_SIGM':

result...=CALC_ELEM(....,OPTION=(....,'ERRE_ELEM_SIGM',),);

The refinement command itself is as follows:

...... print mesh print model

counterp1 = counter+1;

meshcp1=CO('mesh_%d' %counterp1)

MACR_ADAP_MAIL(MAILLAGE_N=mesh[counter],

MAILLAGE_NP1=meshcp1,

ADAPTATION='RAFFINEMENT',

RESULTAT_N=result[counter],

INDICATEUR='ERRE_ELEM_SIGM',

NOM_CMP_INDICA='ERREST',

CRIT_RAFF_PE=0.20,

QUALITE='OUI',

CONNEXITE='OUI',

TAILLE='OUI',

LANGUE ='ANGLAIS');

mesh[counter+1] = meshcp1;

The command takes the current mesh mesh[counter] as input MAILLAGE_N=curmesh and the output mesh is MAILLAGE_NP1=meshcp1. Again, the meshcp1 is not defined (in the Python sense) so we need to use the CO('..') operator on forehand:

counterp1 = counter+1;

meshcp1=CO('mesh_%d' %counterp1)

Further keywords are the ADAPTATION='RAFFINEMENT' together with CRIT_RAFF_PE=0.10. In this case the 0.10 or 10 % of the elements with the largest error estimate (based on stress error indicator INDICATEUR='ERRE_ELEM_SIGM', NOM_CMP_INDICA='ERREST') are refined. The other elements remain untouched. At the end we need to assign the next element of array mesh to the newly defined meshcp1: mesh[counter+1] = meshcp1. In the last iteration no refinement is required, hence the if statement.

Note: I mainly based this command file on the astest example zzzz121a.comm (see links below). In that case the statement immediately after macro command MACR_ADAP_MAIL mesh[counter+1] = meshcp1 is not included. For my examples it doesnot work without this.

The initialisation of the calculation

Here the initialisation commands that can be left out the for loop are described:

DEBUT();

# initialise counters count = [0,1,2,3]; count0 = count[0];

# initialise model parameters mesh=[None]*4 model=[None]*4 Amat=[None]*4 result=[None]*4 Load=[None]*4

#Define material properties steel=DEFI_MATERIAU(ELAS=_F(E=2.1e5,NU=.28,),);

#Read MED mesh file mesh[count0]=LIRE_MAILLAGE(UNITE=20,FORMAT='MED',NOM_MED='mesh0',);

In the array count all the loop numbers 0 to 3 are defined. This is used to control the for loop. The array parameters mesh, model, Amat, result and Load are initialised with maximum size according to the count array.

Furthermore teh material properties are defined and the initial mesh is read.

The for loop construction

# start counter

for counter in count:

model[counter]=AFFE_MODELE(MAILLAGE=mesh[counter],AFFE=_F(TOUT='OUI',

PHENOMENE='MECANIQUE',MODELISATION='3D',),);

#Assign material to mesh

Amat[counter]=AFFE_MATERIAU(MAILLAGE=mesh[counter],

AFFE=_F(TOUT='OUI',MATER=steel,),);

#define boundary conditions and loads

Load[counter]=AFFE_CHAR_MECA(MODELE=model[counter],

DDL_IMPO=(_F(GROUP_MA='Afix',DX=0.0,DY=0.0,DZ=0.0,),

_F(GROUP_MA='Apres',DX=0.0,DY=0.1,DZ=0.0,),),);

result[counter]=MECA_STATIQUE(MODELE=model[counter],

CHAM_MATER=Amat[counter],

EXCIT=(_F(CHARGE=Load[counter],),),);

result[counter]=CALC_ELEM(reuse =result[counter],

MODELE=model[counter],

RESULTAT=result[counter],

TOUT='OUI',

TYPE_OPTION='TOUTES',

OPTION=('EQUI_ELNO_SIGM','SIEF_ELNO_ELGA','ERRE_ELEM_SIGM',),);

result[counter]=CALC_NO(reuse =result[counter],

RESULTAT=result[counter],

OPTION=('EQUI_NOEU_SIGM',),);

unitnumber = 80

IMPR_RESU(FORMAT='MED',

UNITE=unitnumber,

RESU=_F(MAILLAGE=mesh[counter],RESULTAT=result[counter],NOM_CHAM=('DEPL',),),);

##========================##

## define mesh refinement ##

##========================##

if (counter<count[len(count)-1]):

print count, len(count), count[len(count)-1], counter

print mesh

print model

counterp1 = counter+1;

meshcp1=CO('mesh_%d' %counterp1)

MACR_ADAP_MAIL(MAILLAGE_N=mesh[counter],

LANGUE='ENGLISH',

MAILLAGE_NP1=meshcp1,

ADAPTATION='RAFFINEMENT',

RESULTAT_N=result[counter],

INDICATEUR='ERRE_ELEM_SIGM',

NOM_CMP_INDICA='ERREST',

CRIT_RAFF_PE=0.10,

QUALITE='OUI',

CONNEXITE='OUI',

TAILLE='OUI',);

mesh[counter+1] = meshcp1;

#endif

#end for loop

And close the calculations:

FIN(FORMAT_HDF='OUI',);

All the results are now written to a single file on unit 80. In Salome's object browser the results are available after 'file' --> 'import'--> '<resultfile>.med' under mesh_0, mesh_1, mesh_2 and mesh_2. Each mesh contains a DEPL under fields. By adding the LANGUE='ENGLISH' Homard's output will be in English! One small portion of text output that will be easier to understand for non-Fr users.

Remarks on Python language

First note that 'test_%d',%3 will evaluate to 'test_3' in Python. Now suppose counter=1, counterp1=2 then meshcp1 evaluates to 'mesh_2' = CO('mesh_2'). The new name 'mesh_2' is defined. This corresponds to mesh[2].

- Note that the name 'mesh_2' has maximum length of 8 characters, due to (Fortran?) filename limitations.

To check this the print commands print model and print mesh have been added at the start of this block. The output of these commands are e.g:

print mesh,print model,.....:

[<maillage_sdaster(72a5fd0,'mesh_0 ')>, <maillage_sdaster(56ed650,'mesh_1 ')>, None , None] [<modele_sdaster(72becd0,'model_0 ')>, <modele_sdaster(56ed750,'model_1 ')>, None , None] [<char_meca(5af3110,'Load_0 ')>, <char_meca(56fa6d0,'Load_1 ')>, None , None] [<cham_mater(5661fd0,'Amat_0 ')>, <cham_mater(56eb290,'Amat_1 ')>, None , None] [<evol_elas(56e49d0,'result_0 ')>, <evol_elas(56ff690,'result_1 ')>, None , None]

Command control

The Python for loop is controlled by indenting the commands by a fixed number of characters:

maxcount = 4;

for counter in range(0,maxcount):

do_something();

if (counter<maxcount-1):

refine();

else:

donotrefine_or_donothing();

#endif

#endfor

The range command yields:

maxcount=4; xx = range(0,maxcount);xx

--> xx=[0,1,2,3]

The results of the refinement

Some numerical results

The numbers of nodes and quadratic elements (tetrahedrons) of the meshes:

10% 90% new change nodes elements changed unchanged elements factor 4224 2064 206 1858 8796 4958 496 4462 3100 15 (= 3100/ 206) 20043 12029 1203 10826 7567 15 (= 7567/ 496) 45066 28347 2835 25512 17521 15 (=17521/1203)

So, from a single tetrahedron that is refined, 15 tetrahedrons are generated for this mesh.

In an extended calculation, where the number of refinements are increased to five, the following information is reported in the mess file:

elements niveau-----------------------------------level

nodes total 0 1 2 3 4 5

mesh_0 4224 2064 2064 - - - - -

mesh_1 8796 4958 1290 3668 - - - -

mesh_2 20043 12029 496 8757 2776 - - -

mesh_3 45066 28347 69 11727 12259 4292 - -

mesh_4 112313 72762 21 6940 50452 8241 7108 -

mesh_5 272204 180412 0 2132 93176 55159 14843 15066

Hence after 6 iterations, all the elements have been refined, number of level 0 elements is 0.

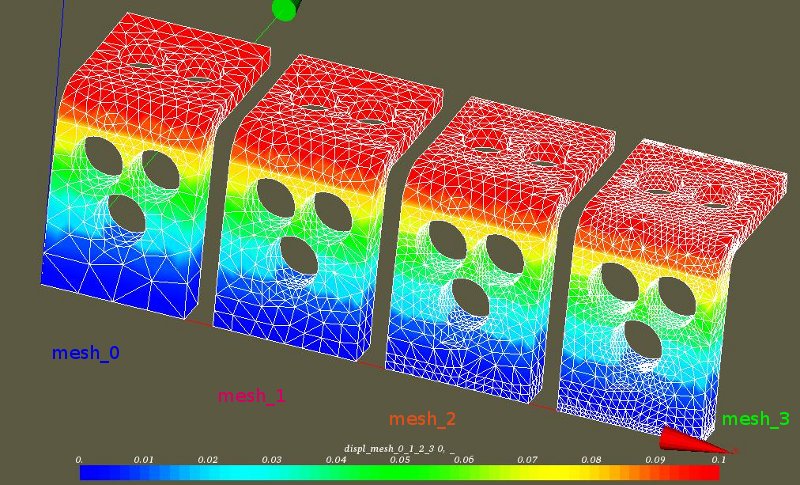

Some graphical results

In the graph below, the original mesh (top left) and the two successive refinements based on the discussed criteria are depicted (bottom right last iteration).

The picture below shows the stress error estimation 'ERREST'. The first refinement from mesh0 to mesh1 is based on this ERREST field.

The ASTK input files

The picture below shows the input and output files defined in ASTK.

Download files

This zip contains the following files

- python geometry and mesh files (load in Salome by File --> Load script (cntrl T)) and right select refresh (F5) in the object browser). Export the med file in the mesh module under mesh0.med for further processing by Code-Aster, controlled by ASTK.

- command files for Code-Aster

- astk file for file control by ASTK

- export file, generated by ASTK.

The result file resx0.med can be viewed in the post processor module of Salome by File --> Import --> resix.med or cntrl I in the object browser. Importing it into the mesh module can be useful to check e.g. the number of elements. All the results of the meshes are stored in separate fields mesh_0, mesh_1, mesh_2 and mesh_3.

Links

More information about the mesh refinement by Homard can be find here:

pdf file: http://www.code-aster.org/V2/doc/default/man_u/u7/u7.03.01.pdf

Homard website: http://www.code-aster.org/outils/homard

- It seems I have to update all pdf links; for now check u7.03.01.pdf by hand on the Code Aster site.

Not really links, but nice to study are the examples

- zzzz121a.comm,

- zzzz121b.comm,

- zzzz121c.comm,

- zzzz121d.comm and

- zzzz121e.comm.

in the astest directory [$ASTER_ROOT]/STA[$VERSION]/astest/.....,

e.g in my case: /cae/aster101/STA10.1/astest/zzzz121a.comm

That's it for now.

Kees